Pickling & Passivation

Pickling

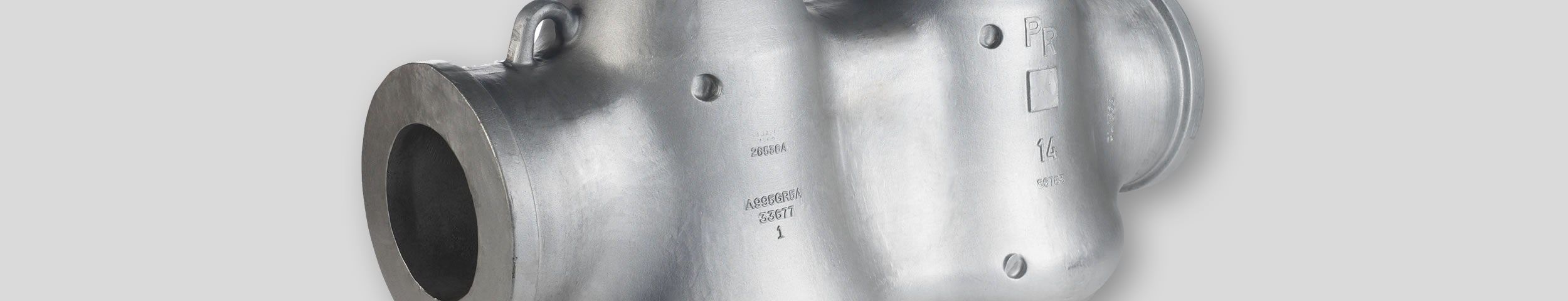

Steel pickling is a metal surface treatment that is used to remove impurities including rust, and scale from the surface of the material. During hot working processes such as forging and casting an oxide layer, referred to as scale develops on the surface of the part.

To remove this oxide layer, the material is submerged into a tank of chemical and this is referred to as metal pickling or steel pickling in the industry. Stainless steels require a two-step pickling process, with additional chemicals used (phosphoric, hydrofluoric, and nitric acid).

Passivation

Passivation means treating or coating a metal in order to reduce the chemical reactivity of its surface. For stainless steel, passivation refers to a process where the free iron is removed from the surface of the metal using an acid solution that prevents rust. After the iron surface has been removed the other components of the alloy such as chromium or nickel still remain as a surface layer over the underlying steel. Upon exposure to air, these elements react with oxygen to form an oxide layer that protects the rest of the steel from corrosion. In a case of mechanical, heat or chemical damage to take place the iron might once again be exposed leading to rusting which is why the passivation process may be repeated again to prevent a re-occurrence.